2012.04.02

New Models Now Available for YC Series of Full-Servo Robots Optimized for Energy Savings and Reduced Vibration

Yushin Precision Equipment Co., Ltd. of Kyoto, Japan has released two new models of their "YC Series" line of fully servo-powered, traverse type robots which embody the latest design optimization methods to save energy and reduce vibration. The two new models go on sale April 2.

Yushin Precision Equipment carries the motto of "Heartful Technology," and is a dedicated supplier of take-out robots for injection molding machines (based in Kyoto, Japan; President Mayumi Kotani; 1.986 billion yen capital).

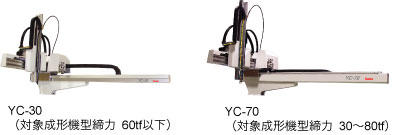

The two new releases are smaller models of the YC Series of robots which initially debuted in July 2011. The YC-30 is sized to fit injection molding machines of 60 tons clamping force or less, while the YC-70 accommodates molding machines in the 30-80 ton range. Each model is available in the single-arm "S" type for molded product take-out only, or a dual-arm "D" type for extraction of both products and runners.

The addition of these two models brings the total number of models in the YC lineup to nine, sized to fit molding machines with clamping forces of anywhere from 30 to up to 450 tons. Customers now have a wider range of YC robots from which to choose.

List price (tax not included) for the YC-30 starts at 2,400,000 JPY, while the YC-70 is priced from 2,600,000 JPY. Yushin's approximate sales target for the two new YC models is 300 units per year. Yushin expects to sell a combined total of 1,500 units for all nine YC models annually.

Conserves Energy

YC Series Features

The YC series integrates design optimization*, which uses logical analysis to reduce the robot's weight and raise its energy efficiency. The YC is also optimized for less vibration, which contributes to shorter overall cycle times. Additionally, YC robots are equipped with a deep selection of standard features, including new controller functions.

Conserves Energy

- 1.Design optimization enabled the use of smaller servo motors, which lowers electricity usage by 26% compared to the previous YA series robot.

- 2. Standard-equipped ECO Vacuum** feature reduces compressed air consumption up to 75%.

- 3. New ECO Monitor** function displays real-time electricity and air usage data.

Suppresses Vibration

- 1. Design optimization, the use of CFRP (carbon-fiber reinforced plastic) material, and anti-vibration controls all combine to reduce arm-settling time by 72%.

- 2. Improved vibration damping for smoother, more precise take-out and handling.

More Standard Features

- 1. Eight features, formerly options, are standard-equipped on the YC series.

- 2.YC robots come standard with the new "Predictive Maintenance" function, which alerts operators if potential trouble symptoms are detected. Maintenance evolves from preventative to predictive on the YC series.

Notes:

* Design Optimization

Design Optimization is what Yushin calls the practice of applying CAE (computer aided engineering) to seek the most theoretically optimal form for a robot based on its mechanisms and motions. This recent engineering approach is used to design lighter weight and increased reliability in automobiles and aircraft.

** "ECO Vacuum" and "ECO Monitor" are registered trademarks of Yushin Precision Equipment Co., Ltd.

[Yushin Precision Equipment Co., Ltd.]

Tel: +81-75-933-9555

Headquarters: 11-260 Kogahonmachi,

Fushimi-ku, Kyoto