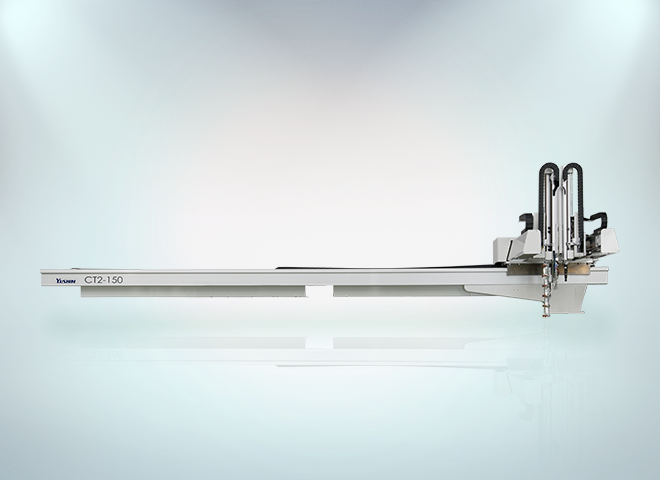

CT/CT2:Clamp-End Traverse Take-out Robots

Concept

Clamp-end traverse type robot for 3-plate mold that releases molded parts to the movable platen side of the IMM

The CT and CT2 transition the former design concept of take-out robots as tools for replacing line operators to the starting point for automating part take-out. Developed from this new concept, these take-out robots provide users with the impetus to completely change the layout of their entire plant.

Features

-

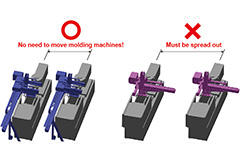

Space-efficient

Because the space between molding machines can be narrowed, more machines can be installed.

-

From runner take-out to producttake-out

Additional space is not required to replace an existing runner take-out robot with either the CT or CT2 product take-out robot.

-

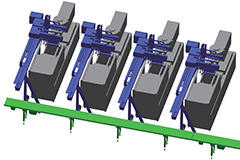

Conveyor belt centralization

Separate conveyor belts are not needed for each molding machine, therefore centralized processing can be used for packaging or inspecting molded parts.

-

![Energy-savings [1]](https://www.ype.co.jp/product/uploads/ycyc2-quality-1.jpg)

Energy-savings [1]

26% less power consumed than by predecessor robotsBecause robot weight reduces by applying Optimum Design approach, lower duty motors are used.

-

![Energy-savings [2]](/en/products/uploads/ctct2-quality-5en.jpg)

Energy-savings [2]

75% less air consumed than by predecessor robotsAir consumption has been reduced by 75% from predecessor models by incorporating Yushin’s propriety ECO Vacuum circuit as a standard feature.

-

Vibration control

72% shorter settling time than predecessor robotsWith the CT and CT2 series, Optimum Design, CFRP and anti-vibration controls combine to shorten settling time (time required for vibrations to fall below a desired level) by 72%, which naturally shortens the full molding cycle.