RAⅡ-α-DW:Double Wing Take-out Robots, Supporting Downstream Equipment

Double wing type (DW) system example

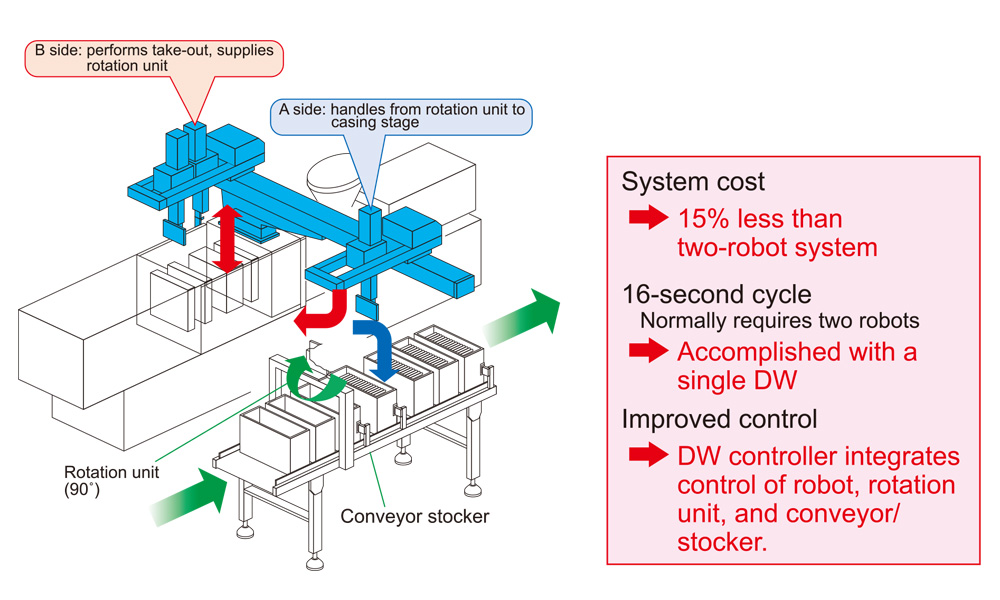

Stocking system application

Aligns and cases molded parts.

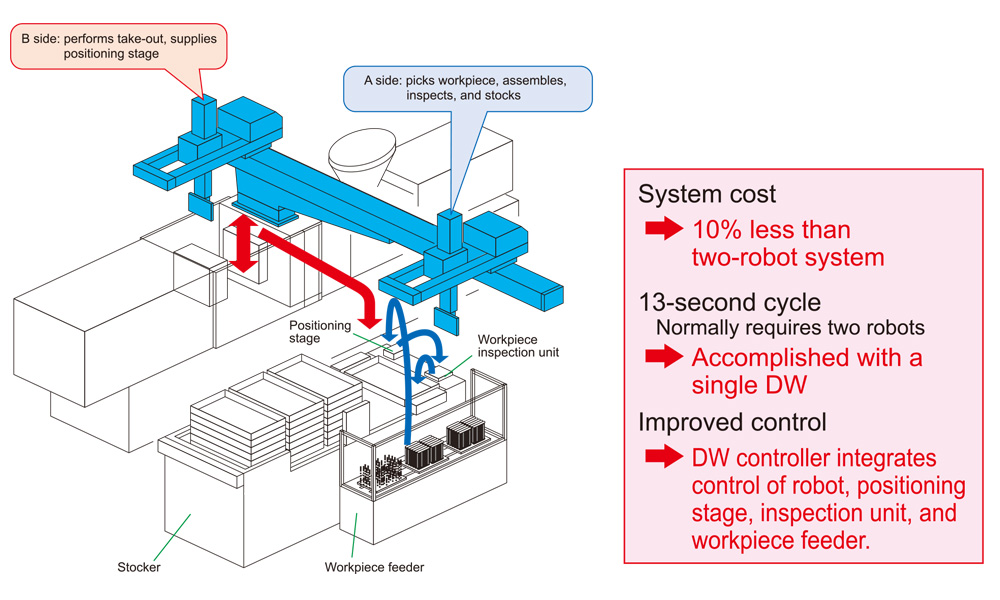

Assembly and stocking system application

Positions the molded part, assembles it with another workpiece, inspects and stocks the final product.

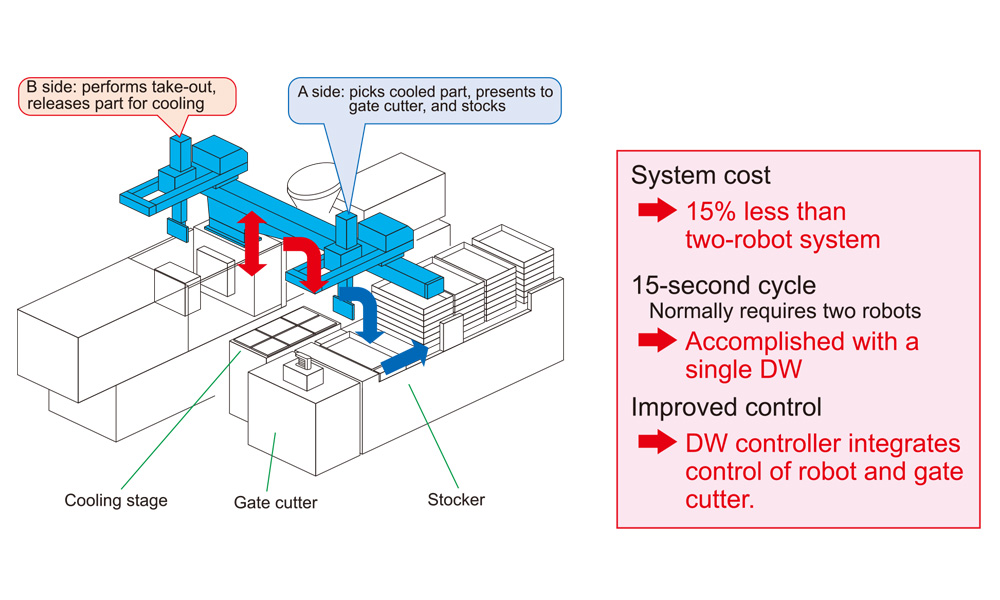

Gate cut and stocking system application 1.

Allows molded part to cool, then performs gate cut and stocks

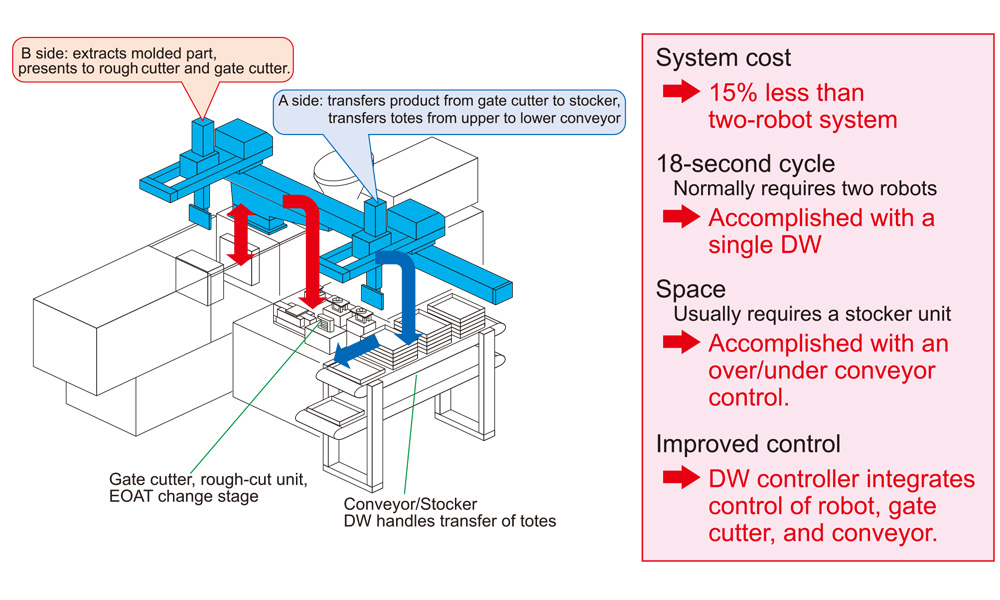

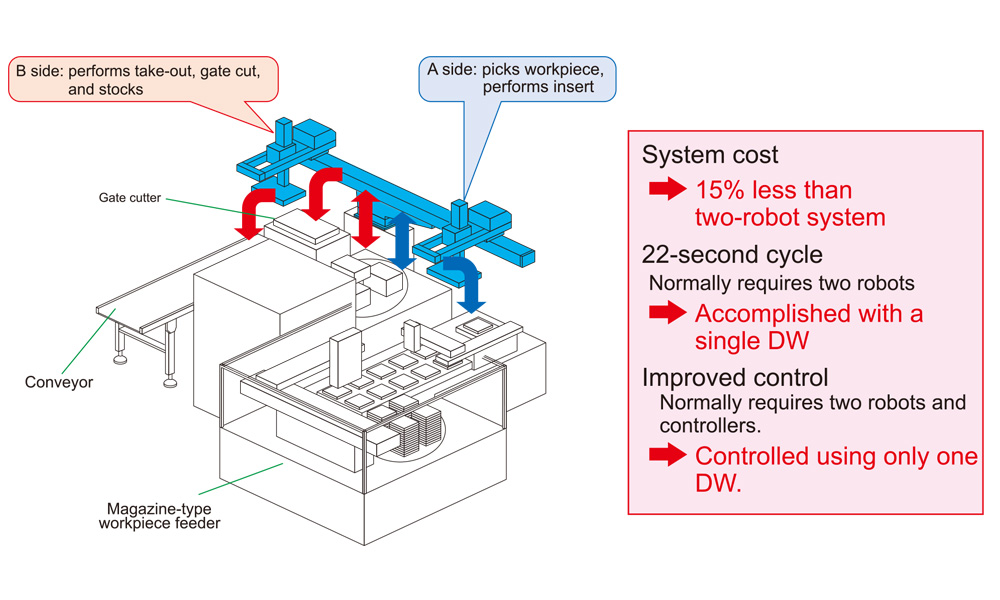

Gate cut and stocking system application 2.

Removes gate and stocks molded part.

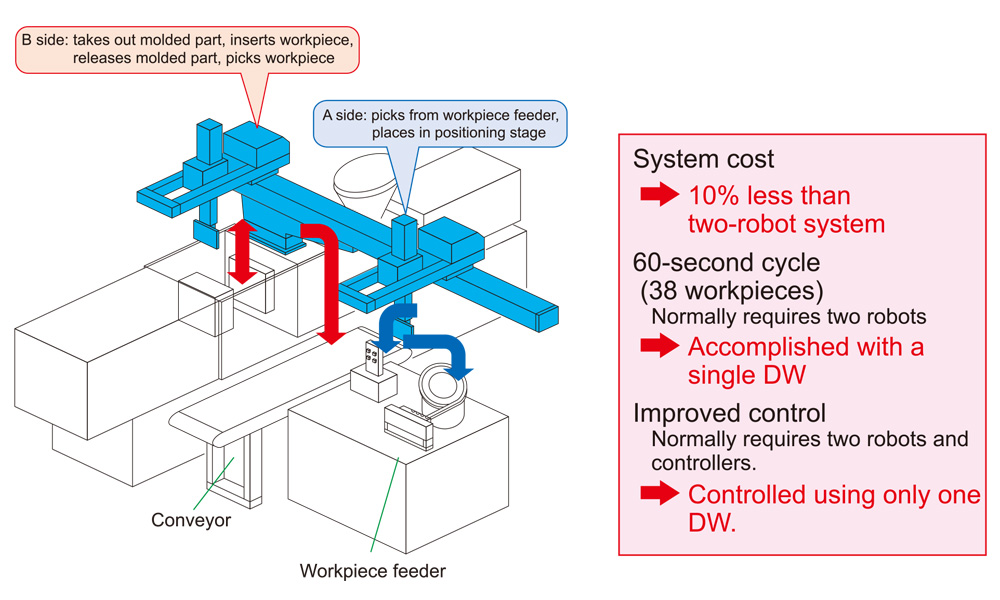

Insert system application 1.

Inserts multiple workpieces

Insert system application 2.(vertical molding machine)

Insertion on A side, extraction on B side.

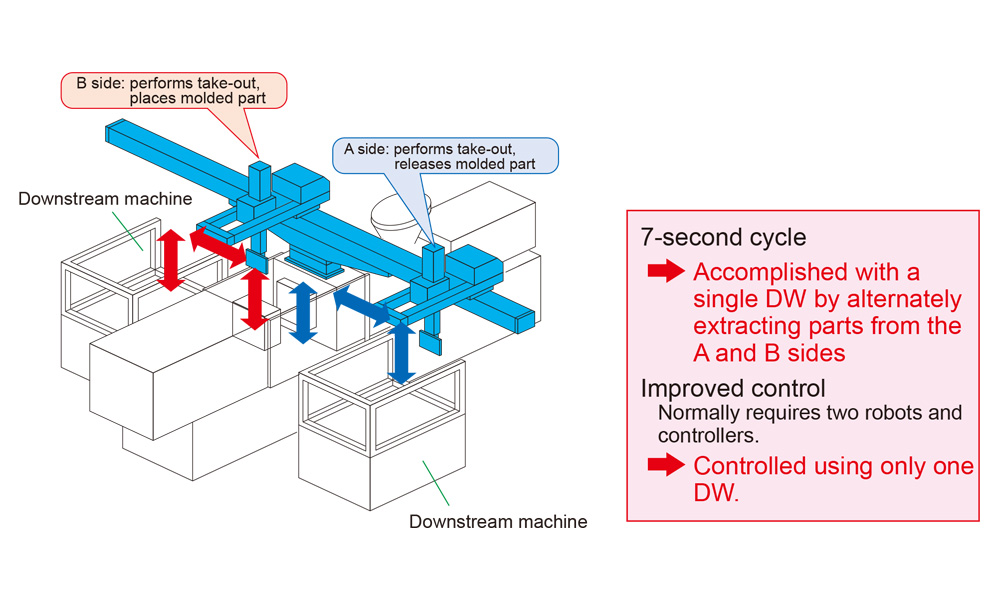

Double capacity robot for high-speed molding system

In a high-speed molding system where time must be allowed for the downstream machine, the A and B sides alternately extract parts for the fastest possible cycle.

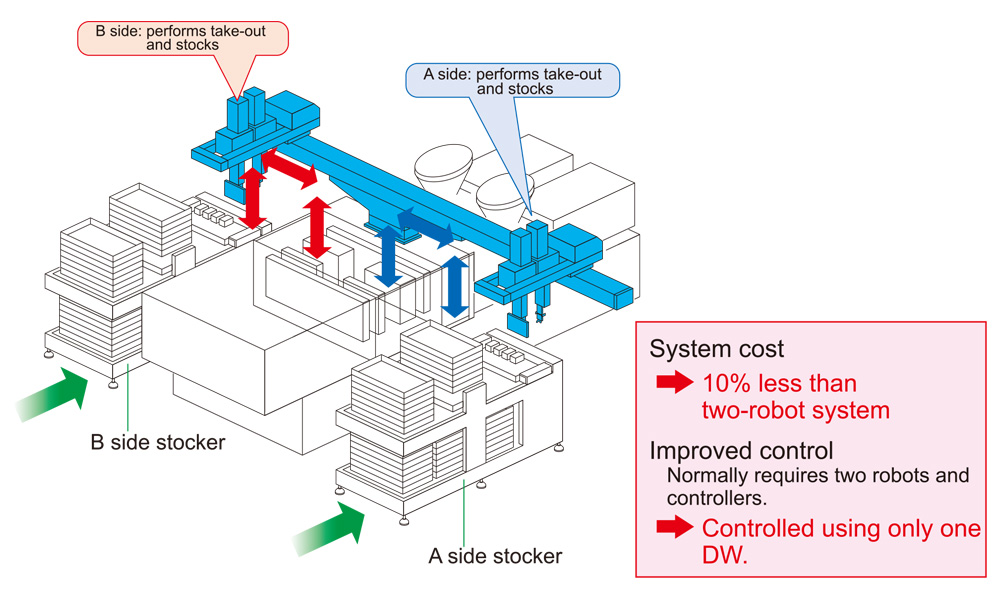

10-axis dual mold system

Take-out and stocking are carried out independently on the A and B sides.

Concept

Features

-

Innovative approach to complicated jobs

With separate units for taking-out and transferring, one Double Wing Robot does the job of two robots.The two units can be operated from the same controller (CPU) and do not require tedious settings. Moreover, complicated operations can be easily programmed by teaching.

-

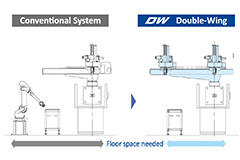

Space-saving

A single Double Wing Robot covers the movements of two conventional robots without taking up the precious floor space around molding machines.

-

Suited for 2-color and different material molding

Equipped with 2 arm unitsA single robot can simultaneously take out both molded parts and runners from a pair of molds on a 2-color molding machine.